We are manufacturer, Exporter and Supplier of metal pipe sleeve and also wall sleeve manufacturing Cut Sheet steel wall sleeves, Wall Sleeves with extended flange connections, Galvanized steel wall sleeves.

What is Wall Sleeve?

Wall sleeves are an option to create a hole penetration in a concrete wall. They are placed into the frame before pouring, and leave a clean hole. A water stop ring is provided. The Wall Sleeves have pipes and conduit running through them that can be sealed with us sleeve product. Our sleeves provide a corrosion-resistant sealing surface for pipes penetrating floors, walls, foundation, or any concrete barrier. The sleeves, offered in steel a 2” water-stop to provide both stability and protection against moisture penetrating the wall. The steel is readily available from stock in 2” through 30” diameter sizes at 12” lengths. Custom lengths and sizes are available upon request. steel wall sleeves suitable for concreting or bricking in. They are supplied in standard lengths of 400 mm and can be easily trimmed to the wall thickness on site. Steel wall sleeves are made of welded or seamless steel pipes. They are Steel to protect them against corrosion. Other corrosion protection measures are available upon request (e.g. electrostatic powder coating).

Provide WS Steel sleeves for all pipes passing through concrete or masonary structures. The WS Sleeves shall be

provided free of welding slag. WS Steel Sleeve sizes though 10” shall be Schedule 40 Steel Pipe or standard wall

thickness. WS Steel Sleeve sizes 12” and larger shall have a .375” or standard wall thickness. WS Sleeves through

wall shall be cast in place and the pipe shall be installed centered in sleeve. The 2” collar, (water-stop) shall be the

same type of steel as the WS sleeve. The collar shall be welded all around on both sides to the sleeve at the point on

the sleeve that positions it at the mid-point of the structural wall when the sleeve is in place. The WS Steel Sleeve

w/water-stop shall be primed inside and outside with Rust-o-Leum red primer #5268 or approved equivalent.

Types of Wall Sleeve.

1. Galvanized Steel Wall Sleeves

Galvanized Steel Wall Sleeves are constructed from steel and available in a wide range of diameters and lengths.

They are an excellent choice for installations where the Link-Seal® Modular Seal and WSG sleeve assembly would be subject to extremely high temperatures or where fire seals are specified.

Provide Galvanized Steel sleeves for all pipes passing through concrete or masonary structures. The WSG

Sleeves shall be provided free of welding slag. Steel Sleeve sizes though 10” shall be Schedule 40 Steel Pipe or

standard wall thickness. WSG Steel Sleeve sizes 12” and larger shall have a .375” or standard wall thickness. WSG

Sleeves through wall shall be cast in place and the pipe shall be installed centered in sleeve. The 2” collar, (waterstop) shall be the same type of steel as the sleeve. The collar shall be welded all around on both sides to the

sleeve at the point on the sleeve that positions it at the mid-point of the structural wall when the sleeve is in place. The

Steel Sleeve w/water-stop shall be galvanized inside and outside

Features and Benefits

- Steel Wall Sleeves available in Painted (Model WS) or Galvanized (Model WSG)

- 2” (50.8 mm) Steel Collar (water-stop)

- Continuous Weld-Bead on both sides of collar (water-stop)

Specifications

- Shall be provided free of welding slag.

- Sizes through 10” (25.4 cm) shall be Schedule 40 Steel Pipe or standard wall thickness.

- Sizes 12” (30.48 cm) and larger shall have a .375” (0.95 cm) or standard wall thickness.

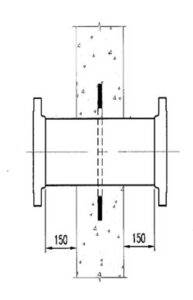

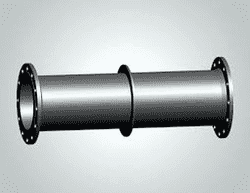

2.Wall Sleeves – Flange to Flange Pipe Connection

Flange to Flange wall sleeves are cast in the wall flush with the wall. The sleeve flange bolts directly to the pipe flange. ANSI flanges used on the wall sleeve welded provides a continuing pipe connection through the wall. Puddle flange water stops welded to the sleeve provide for a leak around waterstop and form an anchoring point in the wall for the sleeve. Protected Hex nuts, dome nuts, thread rod or studs on the back of the flanges provide connection fastener points for the connecting pipe flange.

American and International pipe diameters may be accommodated.

Wall Sleeves WA-WS-FF stainless sleeves are used in WWTP, water treatment facilities, water tanks and other applications for continuing pipe through concrete walls. The FF wall flange seleve fits between the concrete form boards.

Diameter range: up to 60 inches (DN 1600)

Stainless steel: 304L – 316L, scheduled sleeves or metric sleeves are available.

2.Wall sleeves with extended flange connections

Wall Sleeves with extended flange connections: WA-WS.F units, have connection flanges extending out from the wall for connecting pipes through the wall. The sleeve is cast in during wall construction. ANSI 125# or ANSI #150 flat face flanges or raised face may be used.

WA-WS.F double flanged wall sleeves may be grouted in as a retrofit in an existing wall or cast in a new wall.

Wall sleeves for pipes are available for any wall thickness and pipe diameter.

The pipe sleeve flange extends out from the wall for a bolt, washer nut connection and may be a full pipe length or a shorter wall piece.

Stainless steel, carbon steel, galvanized or corrosion protected coatings are available.