We are manufacturer, Exporter and Supplier of Encapsulating Pipe Repair Clamps we manufacturer our all clamps as per your required quantity.

What is Encapsulating Pipe Repair Clamps ?

Encapsulating Pipe Repair Clamp available with delivery worldwide. Also known as a Split Barrel pipe repair clamp, Pressure Containment clamp and Split Sleeve repair clamp.

The encapsulating pipe repair clamp is available in a range of sizes to suit pipe outside diameters from 92.0mm to 1678.0mm. This model of repair clamp is used to fix leaking bell joint connections without removing a pipe or a connection. The clamp comes in two parts and is installed and fitted around the outside of the leaking pipe or joint. The clamp is compatible with all pipe materials. The clamp allows for pipe movements avoiding possible breakages.

These pipe clamps have a ductile cast iron casing, with an EPDM or NBR rubber seal gasket. The clamps are tested to 1600kPa pressure for all sizes. These clamps have an OD tolerance of -6mm to +10mm. The seal of the clamp works by using a progressive lip seal system, which uses internal fluid pressure to help the sealing effect.

Measure the width of the clamp, and mark the length with a permanent marker and tape measure onto the pipe, and an equal distance from the centre of the crack or hole. This will remind you once the clamp is wrapped around the pipe, exactly where to line it up to ensuring the best effect on sealing the hole or crack. When installing this clamp, ensure the correct outside diameter has been measured, clean the surface of the pipe all over the area where the clamp will be fitted.

The vent plug should be removed before installing the clamp, as this allows the fluid to be vented out whilst installation is taking place. The vent plug should be the very last part to be fitted and tightened during the installation process. Start by tightening the middle nuts and bolts first, ending with the outer nuts and bolts. Fasten the nuts and bolts to the required torque mentioned on the clamp itself.

Finally, after 30 minutes of the clamp being in use, check the tightness again with your torque wrench.

Special Specification for Dome Shaped Encapsulating Pipe Repair Clamps:

- The functon of Dome type Encapsulaaon Leak Repair Clamp is to encapsulate any, branch Leaking / Non reliable fi ng on

- The Clamp consists of Two Halves with one half having a Branch

- The Clamp is pressurized unequally due to Dome on one The same needs to be considered during design.

- The Clamp shall be provided with all associated Valves and fii ng for successful and convenient installati Vent Valves, Pressure Gauge and liGin belts are to be provided as a minimum.

- The Clamp shall be suitable for welding to mainline at a convenient time aaGer installatio .

- One Spare set of seal shall be provided in Nitrogen Purged Aluminium

General Technical Specifications for Encapsulating Pipe Repair Clamps

Dome SHAPED encapSULAtng type leak clamp a SSembled with StudS, NUTS and BESt quality SEALIng material whole body aS per the SPECIfiCCati memeoned below:

S. No. |

Description | Parameters |

1 | Design | As per API6H/ ASME SEC VIII DIV.1 / ASME SEC VIII DIV.2 |

2 | Service/ Product to be handled | Petroleum Product |

3 | Suitable for fixing on Spiral / Longitudinal weld pipe of grade |

4 |

Body | i. Carbon steel plates of weld-able quality (Carbon maximum – 0.25%), ii. Shell – ASTM A 516 Gr. 70, iii. Stiffener – ASTM A105. iv. Longitudinal length of leak clamp should be minimum |

5 |

Studs | i. Alloy steel weld able conforming to ASTM A193- B7 / EN- 19 (minimum 7 nos. studs on either side). Preferable size stud (Diameter) should be 7/8”. ii. Studs length 4 nos. (Two on each side) should be 12 inch length and balance 9 inch length. iii. All stud / bolts supplied shall be hot dipped galvanized as per ASTM A 153 |

6 |

Nuts | i. Alloy steel weld able quality confirming to ii. ASTM A194 Gr. 2H/ EN- 8 iii. Spot facing of the nut seal shall be carried out and no washer shall be used for tightening the nuts. iv. All nuts shall be hot dipped galvanized as per ASTM A 153 |

7 |

Sealing Material | i. There shall be sealing ring groove of appropriate size on the inner side of the leak clamp body on periphery of clamp. The mol ded rubber shall cover the groove and covered surface between groove. ii. Best quality “Buna N” rubber packing material iii. Approximately 6 mm thick shall be used. The minimum thickness of packing material on surface of body & outside of groove may be 3 – 4 mm. iv. Shelf life of complete material should be minimum 4 year (confirmation is required from bidder in writing) v. The Seal Material of Clamp shall be suitable for hydrocarbon with following specifications:- · MATERIAL :BUNA N · SHORE HARDNESS: 80 +/- 5 A · TENSILE STRENGTH: 150 KG/CM2 MINIMUM · ELONGATION AT BREAK: 150% MINIMUM. · COMPRESSION SET: 15% MAX. |

8 |

Edge Preparation | i. Edge as per ASME B -31.4 shall be done to be welded including nuts & studs of leak clamp. ii. The circumferental ends shall be chamfered (approx 45 deg.) down to thickness of the pipe (i.e. 0.281”) as per ASME B 31.4, secti n 451.6.2 I 6. |

9 |

Hydro test Pressure | 29.0 kg/cm2 for Class 150 at ambient temperature. 152.0 kg/cm2 for Class 600 at ambient Temperature. 228.0 kg/cm2 for Class 900 at ambient Temperature. The seals shall be replaced upon completion of hydro test. Testing shall be carried out in presence of Owner’s representative. No visual bulge shall be accepted during hydro test. |

10 |

Finishing | Two coats of Zinc Silicate primer with minimum Coati g thickness of 100 micron uniformly applied on body (uncovered by seal) of the leak clamp. |

11 |

Others | Clamps to be painted with airless spray gun. Primer: Zinc Silicate – 75DFT, Intermediate Coat – MIO 50DFT, T op Coat – Epoxy Polyurethane – 40DFT |

Compliance to Specification:

- The bidder should comply with the specificaton in totality and in token of confirmmaon the bidder shall return a copy of specification duly signed &

- Any remark by the bidder in respect of specificaaon shall be mentone d herein below with proper reference to the clause and appropriate reason for the

- Any remark directly or indi rectly on the spec ificaton by the bi dder made else where in the offer shall not be considered by this.

Table 1. Imensions Details for High Pressure Long Seal Leak Clamps

Note: * Tolerance ± 3mm

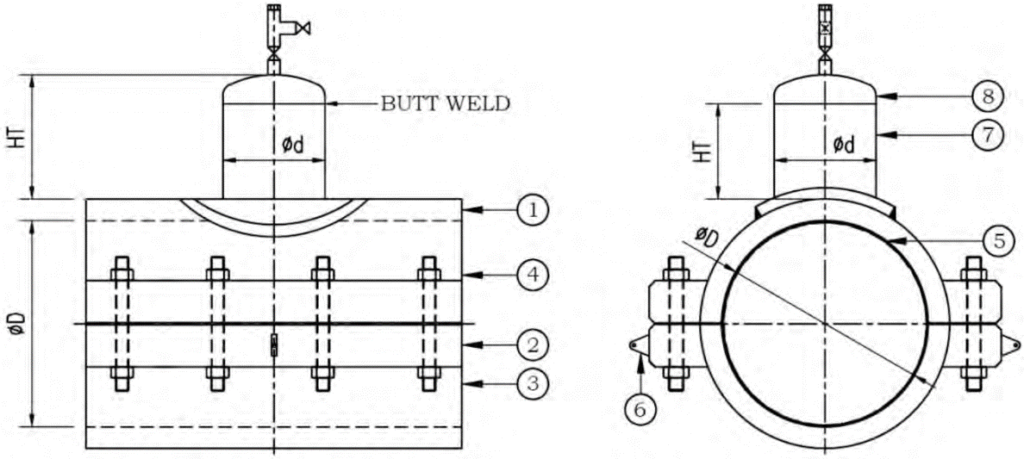

BILL OF MATERIAL | |||

Sr. No. | DESCRIPTION | MATERIAL | REMARKS |

01 | SPLIT BODY SHELL | ASTM A 516 GR 70 |

|

02 | STIFFNERS | ASTM A 105 |

|

03 | STUDS | ASTM A193 GR B7 |

|

04 | NUTS | ASTM A 194 GR 2H |

|

05 | SEALING GASKET | BUNA ‘N’ |

|

06 | LIFTING HOOK | ASTM A 516-70 |

|

07 | BRANCH PIPE | ASTM A 106 Gr B |

|

08 | CAP | ASTM A 234 GR. WPB |

|

Note: Following requirements to be fulfilled by the parres:-

- Approval for QAP and man ufacturing procedure, draw ing of leak clamp, design of e ach clamp, Material test certificates before start of producton / man

Drawings

Size | D | HT | d |

12.75” | 12.75” | 350 mm | 8” NB |

14” | 14” | 350 mm | 8” NB |

16” | 16” | 350 mm | 8” NB |

The numbers 1 to 8 have been detailed in Table-2 for Bill of Material.

We are World Wide Service Provider.

We Manufacturer, Fabricator, supplier and exporter of Encapsulating Pipe Repair Clamps in MIDDLE EAST: Saudi Arabia, Iran, Iraq, Uae, Qatar, Bahrain, Oman, Kuwait, Yemen, Syria, Jordan, Cyprus, AFRICA: Morocco, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Tunisia, Uganda, Ghana, Senegal, Liberia, NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad and Tobago, Jamaica, Bahamas, Denmark, EUROPE: Russia, Norway, Germany, France, Italy, Uk, Spain, Ukraine, Netherland, Belgium, Greece, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Bulgaria, Turkey, Montenegro, Romania, Azerbaijan, Czech Republic, ASIA: India, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, SOUTH AMERICA: Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Peru